OENG1189 Topology Optimization and 3D Printing Assignment 1, 2025 | RMIT

1. Brief Introduction of the Project

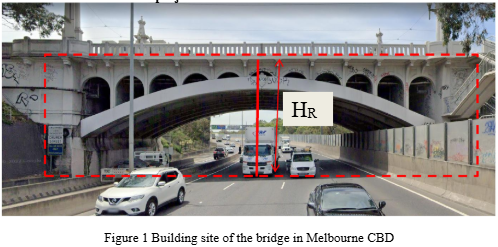

This is an individual task for each student. You are required to conduct a structural optimisation design on a bridge structure using Abaqus to simulate its behaviour. This bridge is supposed to replace an existing Church St Bridge on church St, Melbourne VIC 3141 as shown in Figure 1. Google map coordinates: -37.83384, 144.99664.

You should measure the size of the bridge sites using images you snap-shot on google map. You should use the two red lines in Figure 1 as the scale reference. To personalise the assignment, the height, HR, of the red line on the right side in Figure 1 is 6.00m + the last two digits of your student number, i.e. if you student number is s3543485, then the length of the red line is 6.85m. Please indicate the possible errors in your measurement. You will measure other sizes (i.e. length, width) of the bridge using this size as a reference.

2. Optimisation design

You should follow the optimisation design cycle as illustrated in lecture 1 (or lecture 4 in detail) to do your design. Generally, you will follow two routes. In the first route, you will act as an optimizer with the ESO principle and remove inefficient materials-i.e. regions with lower stress levels. You will get an optimal design manually with at least 3 iterations. The second route is to use the MATLAB code with proper input parameters to get an optimal design. Some detailed guidance and requirements are listed in the following sections.

2.1 Expected design space for optimisation

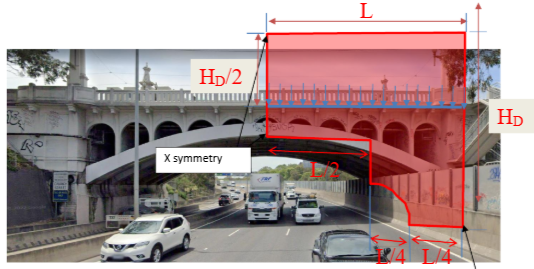

You should determine the approximate sizes of the design space (usually larger than the size of the existing bridge) to be optimised. You should consider the following factors:

- Apply symmetry and consider only half of the bridge;

- Length and depth are the same as the old bridge, height HD can be changed, and is up to k times of the old bridge (k=2+middle two digits of student number/100, i.e., if your student no is s3543485, then k=2+34/100=2.34);

- Enough height (3.5 m or more) for the vehicles to travel under the designed bridge;

- Only the selected region of the bridge will be considered, as outlined by the red dashed line in Figure 1. Foundations and supporting columns are considered rigid enough to be considered as a fixed-end support; no underground support will be considered in your optimisation design.

- The bridge will not change along the out-of-plane direction of Figure 1, so it can be simplified as a 2D bridge with a plane-strain stress state.

- A uniformly distributed load acting on half the height (HD/2) of the bridge is considered. The magnitude of the total load acting on the bridge should be xx kN (first two digits of your student number after 3, i.e., if your student no is s3543485, then your total load is 54 kN).

An example of the acceptable design region is illustrated in Figure 2, and this design domain is used in the MATLAB code provided in Assignment 1.

Figure 2. Example of an acceptable design domain for the bridge

2.2 Material and critical load information of the optimisation design

You are required to design a bridge with an optimal stiffness using concrete. This design is supposed to be constructed by a 3D construction printer. The concrete material has a Young’s modulus of 40GPa and Poisson’s ratio of 0.26. The compressive strength of the fully cured concrete is 40MPa, and the tensile strength is 4MPa. The critical load for validation of your simplified Finite Element Model (FEM) can be considered as a total load of 800kN in the bridge with a maximum deflection of less than 1/250 of the length of the bridge and around 0.3mm.

2.3 Expected content in your report

You are expected to demonstrate the completion and accuracy of the optimisation design in your report. Some detailed guidance and requirements are listed in the following sections.

2.3.1 Expected results from optimisation design

For the manual optimization with ESO, you will provide the following information:

- the topology for each iteration and corresponding parameters, i.e., stress level used, Initial volume of design domain, removed volume in current iteration, volume fraction, etc

- Build the right FEM for the final topology and obtain the maximum deflection

For the optimisation with MATLAB code, you will provide the following information:

- the topology for each optimal design and its corresponding parameters, i.e., input parameters used, volume remained, the maximum displacement, etc

- build the right FEM with optimal topology obtained and present detailed information for one optimal design you choose (preferably with a larger rmin value)

- conduct verification and validation of the optimal design

- vary input parameters and obtain different innovative designs and specify their merits (how it looks, how good are its performance, will it save more materials etc) by comparing it to other designs

You should compare the finite element results from different designs and finalise different innovative designs. For each innovative design, you should provide

- 3D model of the optimal design

- Rendered a view of the optimal design by putting it on the construction site

- Specify the merits of this design by comparing it with other designs

2.3.2 Expected work from finite element analysis

You are expected to use Abaqus to check the performance of your design through the following steps

- provide all required finite element modelling information for the final optimal design (from a 2D model with a topology obtained by MATLAB code). The modelling information includes the parameters used for FEM (Figure to show dimensions, Figure to show boundary, load conditions and mesh, a table to include all used input parameters including material properties, section thickness, step time and increments, pressure value, length of fixed end, approximate global size, element type, element & node number etc.)

- The detailed finite element analysis results of the optimal design (refer to 2.3.3 for details

- build an idealised FE model (an initiative design for optimisation) with a similar topology to the initial design domain shown in Figure 2 for the manual optimisation

- Build the right FEM with the optimal topology from MATLAB Code and verify and validate this FE model, i.e. for validation, the experimental results on a portal frame-like design show that the maximum deflection of the bridge under a total load of 800 kN is around 0.3 mm.

2.3.3 Detailed results from finite element analysis

The following results from finite element analysis using Abaqus should be included in your report:

- Maximum deflection – data in a table

- Distribution of deformation – a screen shot from Abaqus contour plot

- Distribution of Von Mises stress – a screenshot from Abaqus contour plot

- Maximum tensile stress and compressive stress -data in a table

- Load-displacement curve (Load is from the supports and displacement is at the centre point of the bridge) – a graphic plot using Excel or MATLAB, or other professional software

3. Detailed requirements of the project:

In your report, you should provide evidence (Screen shots of contour plot from Abaqus or MATLAB, table for data input, sketch, charts etc) to show the completion of the following required tasks for Project 1:

3.1. Evidence for the major tasks for FEA using 2D FEM with optimal topology from MATLAB code

(It is acceptable to do those tasks through 2D FEM with a topology of the existing bridge if you started your assignment from week 2)

- Geometry modelling of a bridge with detailed sizes

- Material model and corresponding parameters

- Loading conditions and boundary conditions

- Meshing information

- FE model verification-convergence (Software report, force equilibrium, following expectation and mesh convergence check)

- Model validation through comparison of simplified equivalent model with other models and virtual experiment data, i.e., the experimental result on the equivalent model shows that the maximum deflection of the bridge under a total load of 800 kN is around 0.3 mm.

3.2. Major tasks for structural optimisation:

- Overall optimisation design procedure of your structure – flowchart

- Site surveying (Virtual visit is preferred)

- Design domain, objectives, constraints, optimisation statement

- Obtaining manually the optimal results by the ESO principle and its iteration steps (at least 3 iterations), and optimal design using MATLAB code with the right input parameters

- Verify, validate and render your optimal design by comparing the results from the previous with the ones from the BESO method (BESO2D_Bridge2025.m).

- Applying different geometry constraints to obtain different innovative designs and identifying the merits of each innovative design by comparing it with other designs.

3.3. Video presentation:

- The total presenting time is -3 minutes

- Project introduction – optimisation design of a bridge in Melbourne, locations, requirements, optimisation design procedure and results

- Merits of your recommended optimal design

- Your feelings on your first project in this course and expectations for future assignments.

3.4 Brief marking rules

The total mark for this assignment 1 is 30 marks. There will be 5 criteria to mark this assignment.

Criteria 1 – Accuracy. The modelling information, procedures and results are accurate.

Criteria 2 – Completeness. All required tasks should be completed for this project 1.

Criteria 3 – Professional Report. The report is written professionally.

Criteria 4 – Innovative. The final optimal structures obtained should be innovative.

Criteria 5 – Presentation. A clear video report to illustrate the overall project and its outcomes.

More detailed information to earn marks can be found in the detailed marking rubrics as attached at the end of this assignment illustration.

4. Penalty for late submission of the project:

Late submission of this assignment will incur a penalty of 5% of the total mark of this assignment for each day after the due date.