WM9F1-15 Procurement and Inventory Management Assignment Brief and Front Sheet PG

WM9F1-15 Assignment Brief and Front Sheet PGT

This front sheet for assignments is designed to contain the brief, the submission instructions, and the actual student submission for any WMG assignment. As a result the sheet is completed by several people over time, and is therefore split up into sections explaining who completes what information and when. Yellow highlighted text indicates examples or further explanation of what is requested, and the highlight and instructions should be removed as you populate ‘your’ section.

This sheet is only to be used for components of assessment worth more than 3 CATS (e.g. for a 15 credit module, weighted more than 20%; or for a 10 credit module, weighted more than 30%).

To be completed by the student(s) prior to final submission:

Your actual submission should be written at the end of this cover sheet file, or attached with the cover sheet at the front if drafted in a separate file, program or application.

Student ID or IDs for group work e.g. 1234567

To be completed (highlighted parts only) by the programme administration after approval and prior to issuing of the assessment; to be consulted by the student(s) so that you know how and when to submit:

|

Submission date (excluding extensions) |

Tuesday 16th September 2025 by 12:00pm (UK Time) |

|

Submission guidance |

To be submitted electronically via Tabula |

|

Late submission policy |

If work is submitted late, penalties will be applied at the rate of 5 marks per University working day after the due date, up to a maximum of 10 working days late. After this period the mark for the work will be reduced to 0 (which is the maximum penalty). “Late” means after the submission deadline time as well as the date – work submitted after the given time even on the same day is counted as 1 day late. For Postgraduate students only, who started their current course before 1 August 2019, the daily penalty is 3 marks rather than 5. |

|

Resit policy |

If you fail this module and/or component, the University allows students to remedy failure (within certain limits). Decisions to authorise resits are made by Exam Boards. These will be issued at specific times of the year, depending on your programme of study. More information can be found from your programme office if you are concerned. If this is already a resit attempt, this means you will not be eligible for an additional attempt. The University allows as standard a maximum of two attempts on any assessment (i.e. only one resit). Students can only have a third attempt under exceptional circumstances via a Mitigating Circumstances Panel decision. |

To be completed by the module leader/tutor prior to approval and issuing of the assessment; to be consulted by the student(s) so that you understand the assignment brief, its context within the module, and any specific criteria and advice from the tutor:

|

Module title & code |

Procurement and Inventory Management WM9F1-15 |

|

Module leader |

Dr Ahmed Tarek El-Said |

|

Module tutor |

Dr Ahmed Tarek El-Said, Dr Ibrahim Ali, Mr Philip Cullen |

|

Assessment type |

Written Report |

|

Weighting of mark |

50% |

|

Assignment brief |

|

Please refer to details in assignment brief below. |

|

Word count

|

2000 words +/- 10% Word count includes everything in the main body of the text (including headings, citations, quotes, lists, etc). Any title page, table of contents, table of tables, table of figures, content within figures/tables, list of references and any appendices are excluded. |

|

Module learning outcomes (numbered) |

1. Critically evaluate different procurement and inventory management strategies, processes, and organizational concepts and their links to further areas of the logistics system. 2. Develop and evaluate supplier selection systems under different supply chain scenarios within the procurement and inventory management processes. 3. Implement advanced techniques to calculate adequate stock levels for different stock categories considering logistics and financial aspects 4. Manage procurement and inventory risks arising from dynamic market structures to achieve a more resilient, sustainable supply chain. 5. Monitor and assess procurement and inventory performance through the use of specialised performance measurement tools and techniques. |

|

Learning outcomes assessed in this assessment (numbered) |

LOs: 1, 3, 4, 5. |

|

Marking guidelines |

Included at bottom of document |

|

Academic guidance resources |

Refer to the Module reading list, Module Moodle pages and verbal assignment guidance from the Module Tutors during the Module. |

WM9F1-15 Assignment Brief

Semiconductor Chips Case Study

‘When chip shortages first shut down automotive production lines in 2021, the semiconductor industry found itself in an unaccustomed spotlight. Suddenly everyone was talking about the tiny chips that enable so many different car functions, from interior lighting to seat control to blind-spot detection. When some high-tech and consumer-electronics companies began to experience chip shortages or voiced concerns about supply chains, the attention intensified. It’s now clear to all: We are living in a semiconductor world’ (World Economic Forum, 2022).

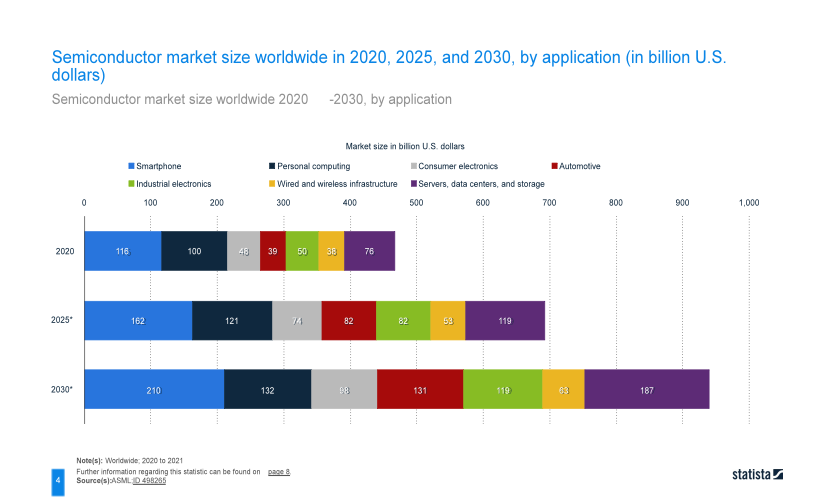

‘Over the last decade, revenues generated by the global semiconductor industry have steadily increased, surpassing 550 billion U.S. dollars in 2021. In the coming years, semiconductor market revenues are expected to grow further, with predictions suggesting that the market will grow once more in 2022 to more than 600 billion U.S. dollars’ (Statista, 2022).

Figure 1 shows the market size for the semiconductor market worldwide.

Figure 1: Semiconductor market size worldwide by application (Statista, 2022)

The Covid-19 pandemic brought a multitude of disruptions that heavily affected the semiconductor, or chip, supply chain. Automakers cut their chip orders in early 2020 as vehicles sales fell (Burkacky et al., 2022). However, by the time demand recovered faster than was anticipated in the second half of 2020, the industry had already repositioned its sales to meet demand from other applications (World Economic Forum, 2022).

Do You Need WM9F1-15 Assignment of This Question

Order Non Plagiarized Assignment

However, the current chip shortage is unlikely to be resolved soon, partly because of the complexities of the semiconductor production process. Typical lead times can exceed four months for products that are already well established in a manufacturing line (see Figure 2 below, Burkacky, et al., 2022). Increasing capacity by moving a product to another manufacturing site usually adds another six months (even in existing plants). Switching to a different manufacturer typically adds another year or more because the chip’s design requires alterations to match the specific manufacturing processes of the new partner. And some chips can contain manufacturer-specific intellectual property that may require alterations or licensing.

‘Many companies that need semiconductors are already reconsidering their long-term procurement strategies. Some, for instance, may shift from a “just-in-time” ordering model, which helps minimize inventory costs, to one in which they order semiconductors far in advance. For their part, many semiconductor companies are adjusting their long-standing strategies to remain strong’ (World Economic Forum, 2022).

Figure 2: Lead time for semiconductor production (Burkacky, et al., 2022)

You have just been hired by one of the leading automotive companies as their Chief Procurement Officer. The company is currently facing considerable delays and stoppage on their production lines due to shortages of semiconductor chips in all electronically controlled components. You have been asked to develop a new procurement strategy and processes for semiconductors, considering the new global market environment.

Q1. Inventory Management

Identify and recommend suitable inventory management tools and control policies that could be implemented to increase resilience across the semiconductor category. Discuss which performance indicators you would apply as a measure of your inventory resilience. (Hint: consider integrating 9-box model, different forecasting techniques, predictive analytics, service level and review level in you answer development).

(This question should be answered within 2,000 words with a 10% +/- allowance. The question is awarded 100 marks and covers Learning Outcomes 1, 3, 4, & 5).